Nader Asnafi

Asso. Professor

Luleå University of Technology, Sweden

Speech Title: Greenness of and cyber-physically controlled systems for metal additive manufacturing

Abstract: Greenness of and cyber-physically controlled systems for metal additive manufacturing is discussed in this presentation. Laser-based Powder Bed Fusion (L-PBF) is the additive manufacturing method and production tooling made by L-PBF for cold and hot working and injection molding are the applications that this presentation is focused on. To accomplish greenness from a production perspective, it is important to use production tools that are designed and optimized for efficient performance in operation (through their life cycle) and made by L-PBF. Efficient performance in operation is defined as optimized cooling (or heating), minimized cycle time, minimized material usage, minimized energy usage, no scraps, no production stops, minimized maintenance, full repairability and remanufactureability, and tool life extension. The toolmaking costs of a L-PBF inclusive process need to be reduced significantly. The total costs (part costs including the tooling costs) are however smaller with efficiency optimized hot working and injection molding tools or dies that are made by L-PBF.

Ng Yin Kwee

Asso. Professor

School of Mechanical & Aerospace Engineering, Nanyang Technological University, Singapore

Speech Title: AI of wake velocity and turbulence intensity of an axial wind turbine

Abstract: In this talk, three machine learning (ML) algorithms viz. Support Vector Regression (SVR), Artificial Neural Networks (ANN), and Extreme Gradient Boosting (XGBoost) are implemented to predict wake velocity and turbulence intensity from a wind turbine at different downstream distances. To this end, a set of high-fidelity numerical simulations are performed for the NREL Phase VI wind turbine to produce training and test datasets for the three machine learning algorithms. Using the trained model, the wake flow field downstream of the blade and turbulence intensity are predicted on the test datasets which are hidden from the trained model. The prediction of wake velocity deficit and turbulence level in the wake from the machine learning algorithms are commensurate to the Computational Fluid Dynamics (CFD) simulations while running as fast as low-fidelity wake models. The wake velocity and turbulence intensity obtained from the ML models are also compared with some of the analytical wake models. The results reveal that machine learning-based algorithms can approximate wake and turbulence intensity characteristics better than the traditional analytical wake models.

Akhilesh Kumar Singh

Asso. Professor

Department of Mechanical Engineering, Aditya College of Engineering & Technology, India

Speech Title: Design and Study on Process Parameters Develops for TIG Welding to Improve Weld Quality

Abstract: Tungsten Inert Gas (TIG) welding (also known as gas tungsten arc welding (GTAW), wolfram inert gas (WIG) and Argonarc or Heliarc welding, though, has many good features in its name and its applications in various fields. TIG welding process is used in the industry due to its positional suitability, reasonable control over metallurgical and mechanical properties and weld integrity. It makes this process more suitable to weld the root pass in the piping and thick materials in industries. However, there are remarkable limitations, such as lack of penetration and welding current beyond a specific limit, reducing its application in welding. Many research works have been carried out to overcome this limitation. Researchers worldwide developed variants of TIG to improve the weld quality, productivity, weld penetration and its applications…

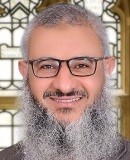

Mohamed H. Saied

GM, Electrical Engineering Dept.,

Abu Qir Fertilizers & Chemical Industries Company (AFC), Alexandria, Egypt

Speech Title: The Power Highways: -HVDC versus HVAC Transmission lines

Abstract: The first electric generator was the direct current (DC) generator, and hence, the first electric power transmission line was constructed with DC. Despite the initial supremacy of the DC, the alternating current (AC) supplanted the DC for greater uses. This is because of the availability of the transformers, poly-phase circuits, and the induction motors in the 1880s and 1890s. Major milestones in the development of high voltage direct current (HVDC) technologies and concepts were achieved in 1950s. Thanks to the high power thyristor switches (1960-70s), the HVDC technologies reached a significant degree of maturity in 1980s. The classical HVDC uses thyristor-based current-sourced line-commutated converter (LCC) technology. The advent of power semiconductor switches in 1980-90s, with turn on-off capabilities especially the IGBTs and IGCTs, and the on-going progress in this field, have introduced the conventional (two-level) voltage-source converter (VSC) technology and its variety of configurations, multi-level and multi-module VSCs, also as viable converter technologies for power system applications…

Hongtao Tang

Asso. Professor

Wuhan University of Technology, China

Speech Title: Intelligent scheduling and the development & application of MES system in hydraulic cylinder manufacturing

Abstract: Under the framework of the Industrial Internet, explore the complete set of flexible construction theories, methods, technologies and software for the production and manufacturing process of high-end hydraulic cylinders. Solve the problems of high-end hydraulic cylinder manufacturing whole process system reconstruction and optimization difficulty, manufacturing whole process resource scheduling optimization difficulty, manufacturing whole process resource control system landing difficulties, etc., significantly improve the high-end hydraulic cylinder production factors optimization configuration and collaborative operation efficiency. Establish a high-end hydraulic cylinder processing and assembly full-process production scheduling optimization framework, carry out research on the two-stage scheduling optimization method of the flexible operation workshop in the pre-machining stage and the flexible operation workshop in the post-assembly stage, and develop a customized MES system based on this model framework, which is of great significance for realizing the data-driven hydraulic cylinder manufacturing whole process system reconstruction and realizing the distributed resource regulation of the system under dynamic disturbance and the multi-objective optimization of the whole process.

The Fifth International Conference on Mechanical, Electric

The Fifth International Conference on Mechanical, Electric